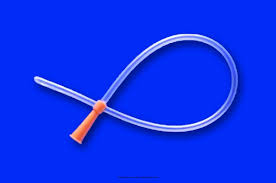

Lubricious, friction resistant and biocompatible SENSCOAT™ coatings can be applied to catheters, guide wires and other interbody application devices. These coatings helped to improve patient's comfort at the time of operation make easier processing at the same time.

As of Magnano, we can supply coating solutions from standard products or customize these solutions according to material properties and production process you want. After all we give a support our customers for the best performance.

While we can currently coat material surfaces such as PVC, Polyurethane, Nylon and Pebax, our studies about coating different materials like Teflon and Fep is going on.

Ürünler

PVC Catheter Coatings

This coating process consists of base coat (MC1011®) and top coat (MC1012®) application. The performance properties like lubricity and intagrity are obtained from top coat. Base coats use as a interface layer by reason of the fact that top coat does not have chemical functionality to bind a surface.

- Transparency

- Excellent and low friction

- Wear resistance

- Low particulate counts

- Biocompatible

|

|

One-Step Hydrophilic Coating for Polyurethane Surfaces

The required lubricity on Polyurethane materials can be obtained with MC2010® without needing base coat. Therefore the coating process time gets shorter. .

- Excellent and low friction

- Wear resistance

- Low particulate counts

- Biocompatible

- Largely ease of application

|

|

Pebax and Nylon Coatings (Guide Wire and Catheter)

Especially it can be applied to neurovascular catheter, cardiovascular catheter and guide wires. We have two different products depending on production process and coating properties of material that will be used. Our MC3011 (base coat)-MC3012 (top coat) and MC3021 (base coat)-MC3022 (top coat) products were developed for Pebax and Nylon systems.

- Excellent and low friction

- Improved wear resistance

- Low particulate counts

- Biocompatible

|

|